|

Magnetic cover lifters are an innovation that protects the worker from injury at work, but also speeds up the necessary work and thus saves your time and money.

They prevent injuries to workers' backs There is no unnecessary waste of time during work The risk of accidents at work is reduced to a minimum They are suitable for all conditions and almost all types of covers of all sizes and weights They are aligned with ISO quality standards They are safe, simple, easily portable, maximally adaptable and are an ergonomically correct solution! Some lid models are also available in ATEX version! In addition to magnetic lid lifters, our offer also includes portable plastic protective barriers and portable plastic protective fences, easy to use and ideal for transport! Contact us at [email protected] or by calling +385(0)1 3874 334 and find out more!

0 Comments

We offer you affordable pre-configured robots or robots made exactly according to your requirements!

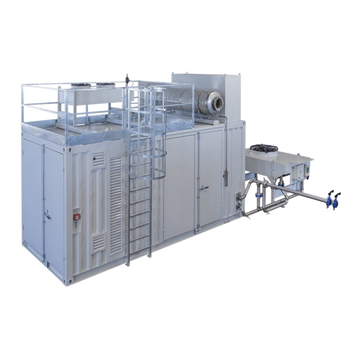

At a time when the main problem has become the lack of manpower, and the imperative in the industry is to reduce costs & increase efficiency, process automation has become crucial. More and more companies are turning to robotics as a solution to these problems, along with the numerous advantages it brings with it. We offer you robots at favorable prices, already made as a finished solution or we assemble them according to your needs. It is important to note that the robots we offer do not need lubrication, are simple and easy to maintain, can work in all weather conditions and are very intuitive. Advantages of automatization of business processes: Reduction of the workforce Greater efficiency Expense reduction Reducing the possibility of error Speeding up the process Greater security Increasing profits. ReBeL® light robot a robotic arm weighing only 8.2 kg with the functions of a collaborative robot plug-and-play solutions, with the control system integrated into the housing or available as an Open-Source variant available ROS nodes total load capacity: 2 kg Robolink® robotic arm A modular approach Low price High flexibility: freely chosen end effectors Lightweight construction Accuracy ≤ 1 mm 2-5 degrees of freedom (DOF) No lubrication Robotic systems they come with options of 2 or 3 moving axes, depending on the user's requirements, that is, the requirements of the application for which the robot system is intended. Depending on the application, we offer ball or sliding robot systems, which enable the system to work in various conditions, such as high or low temperatures, high humidity, and the like. We offer a "turnkey" option, which means that our project team participates from the very beginning in finding the best system and putting it into operation. LEARN MORE>> Delta robots The first linear modular kit for delta robots. drylin® delta robots can be assembled quickly and easily. Thanks to the light design consisting of aluminum and plastic, the system achieves a speed of 60/min in the installation space up to ø 380 mm. The entire kinematics can be delivered ready for installation in the transport frame or as a set of accessories. No additional lubricants are required and almost maintenance-free Fast movement possible due to parallel kinematics Compact and lightweight design  By cogeneration we mean the combined production of electricity and thermal energy in one plant. Cogeneration systems are known under the acronym CHP (Combined Heat and Power). Normally, electricity and thermal energy are produced separately. Thermal power plants are mainly used for the production of electricity, which disperse the resulting low-temperature thermal energy into the environment, while boilers are used for the production of thermal energy, which convert primary energy, which is fuel with high thermodynamic values, into thermal energy of reduced thermodynamic values. If the User's needs require the simultaneous production of electricity and heat, instead of installing a boiler and buying electricity from the grid, modules, or cogeneration systems, can be installed. Following the above, it is intuitive that such a system saves energy, which is a consequence of lower fuel consumption. Advantages of the cogeneration system:

We also offer heat exchangers that come with cogeneration modules, resulting in a final product that fully meets the customer's needs. We offer you "turnkey" for cogeneration modules - installation, commissioning and service services! With each cogeneration module that we offer, it is possible to achieve trigeneration (combined production of thermal, cooling and electrical energy) by adding an absorption cooling device to the system. Cogeneration and trigeneration modules are widely used:

We offer a return on investment calculation service! Turbo - Lux 3 - fire pump test flow gauge - recognized and approved!  The German company Mecon, with 88 years of experience in the production of flow meters and level indicators, stands out for products of exceptional quality, efficiency and reliability. Turbo - Flux 3 is the first, and at the same time the only, flow test gauge for fire pumps that is approved by all 3 institutes (FM, LPCB and VDS)! Dimensions: 3"/DN80

Maximum operating pressure: 16 bar Pump: 200 USGPM (757.08 l/min) Flow: 80 - 400 USGPM (302.83 - 1514.16 l/min) Manufactured: 2021 Our partner is specialist in the production of the highest quality nozzles for unblocking! Long-term tests of water efficiency, energy savings and nozzle power have been conducted by the best engineers in the field of hydraulics! Nozzles available in sizes from 1/8 "to 1"!  Application:

Don't forget to contact us for your special offer!

Perfect linear movements - pneumatic cylinders for correct drive at all times!

For your inquiries please contact us at: [email protected] We offer fans for all types of industries: centrifugal, axial, roof!

Possible fan design in accordance with your requirements! At the customer´s request, available ATEX fan performance and independent rotor performance! Technical properties of industrial fans:

|

AuthorWrite something about yourself. No need to be fancy, just an overview. Archives

August 2022

Categories |